Custom Wig System

Digital technology makes wig fit comfortable and efficient

Benefits of a custom hair system

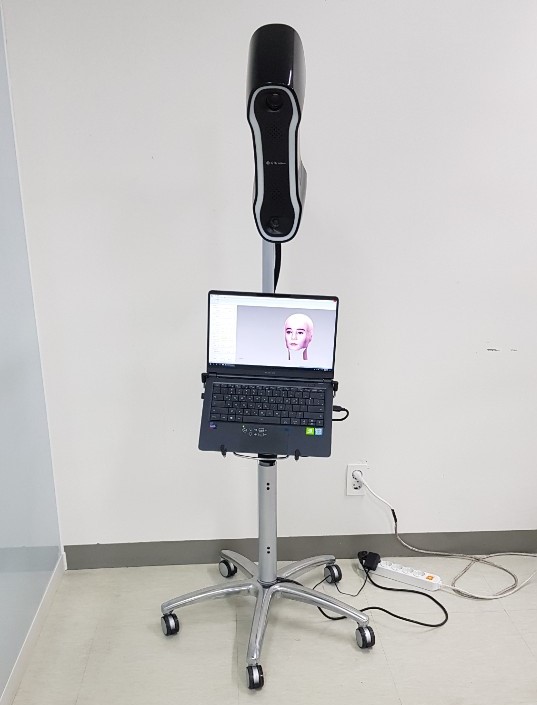

Seowoo Digital Custom Wig Solution uses 3D scanning and 3D printing to improve the inefficiency of manual labor and the shortcomings of existing solutions.

Measure the two phases with a 3D scanner

- Much less customer inconvenience

- Modern store image

- Reduces work time compared to manual work

Transfer data online

- Reduce the cost of shipping patterns to factories

- Reduce the time to transport patterns to the factory

Mold processing with a 3D printer

- 3D printers cost 2-3 million won. Only about 40-50%, compared to CNC

- No fear of carcinogen urethane dust when produced with CNC

Problems with traditional patterning

Most wig stores only have custom wig patterns in the traditional 듧 way. So there are the following problems:

- A pleasant consumer experience (the process of creating a double-sided pattern (pattern, template) with vinyl and tape)

- High international shipping costs

- Long international shipping periods

- Mold making requires the manual work of an experienced person

- Difficulty communicating between stores and factories

Challenges with traditional 3D scanner technology

Today, there are 3D scanner-based solutions for customizing wigs. Led by the founder of West Digital, the solution developed in 2001 is being used by a large domestic wig company.

However, most stores have major barriers and challenges to use.

- Currently, domestic wig companies that are using the solution do not provide solutions to other companies.

- The existing solution is a CNC machine in the wig factory to make a hair-like mold. More than 100 million won is required to purchase CNC machines. It is the amount of money that is very much borne by a small factory.

- Urethane dust, a carcinogen, occurs during CNC manufacturing. It is a problem for increasingly tightening environmental regulations and, above all, dangerous to worker health.

Get news from the launch

Subscribe to the news from The Capital. Be the first to know about the launch of the product we're preparing.